Delta IV program

Air-Attack.com > Space > Delta IV program

Evolved Expendable Launch Vehicle

ST. LOUIS, Nov. 20, 2002 - In a spectacular evening launch today, the first flight of the Boeing (NYSE: BA) Delta IV family of rockets successfully delivered the commercial telecommunications satellite W5 for Eutelsat S.A.

The Delta IV lifted off at 5:39 p.m. EST from Space Launch Complex 37B, Cape Canaveral Air Force Station, Fla. Approximately 37 minutes after liftoff, the rocket deployed the W5 spacecraft to a geosynchronous transfer orbit with a perigee of 539 kilometers above the Earth.

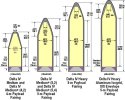

The Delta IV family blends new and mature technology to launch virtually any size medium or heavy payload into space, with the largest success being the now flight proven RS-68 engine. The Delta IV is composed of five vehicle configurations based on a common booster core (CBC) first stage powered by the RS-68 engine.

Delta IV second stages are derived from the Delta III second stage, using the same RL10B-2 engine, but with two sizes of expanded fuel and oxidizer tanks, depending on the model.

In designing the five Delta IV configurations, Boeing conducted extensive discussions with government and commercial customers concerning their present and future launch requirements.

Proven technical features and processes were carried over from earlier Delta vehicles to Delta IV. New technologies and processes were incorporated where they added capability or reduced cost.

RS-68 Main Engine

Delta IV uses the new Boeing Rocketdyne-built RS-68, the first new American-made liquid hydrogen/liquid oxygen engine, which produces 2,891 kN (650,000 lb) of thrust.

This engine is mounted on a CBC first-stage structure, which has been designed for ease of manufacture.

Thirty percent more efficient than conventional liquid oxygen/kerosene engines, the RS-68 is environmentally friendly, producing only steam as a combustion by-product

Vehicle configurations

Delta IV Medium

The Delta IV Medium vehicle is built around the CBC first stage and includes the baseline second stage derived from the Delta III, but with stretched fuel and oxidizer tanks for increased performance. This Delta version can lift up to 4,210 kg (9,285 lb) to geosynchronous transfer orbit (GTO). The payload is encapsulated in a 4-m (13.1-ft) diameter fairing for protection.Delta IV Medium-Plus

| Vehicle Name | Fairing Diameter | Number of GEMs | GTO Payload |

| Delta IV Medium-Plus (4,2) | 4 m (13.1-ft) | 2 | 5,845 kg (12,890 lb) |

| Delta IV Medium-Plus (5,2) | 5 m (16.7-ft) | 2 | 4,640 kg (10,230 lb) |

| Delta IV Medium-Plus (5,4) | 5 m (16.7-ft) | 4 | 6,565 kg (14,475 lb) |

Three Delta IV Medium-Plus vehicles use the common booster core (CBC) and are augmented by either two or four 60-in solid rocket strap-on graphite-epoxy motors (GEMs).

These vehicles are designated first by the diameter in meters of the upper stage and payload fairing and then by the number of GEMs added to the first stage for boost assist; for example, (4,2).

The Delta IV Medium-Plus (4,2) vehicle uses the same second stage and tanks as the Delta IV Medium.

The Delta IV Medium-Plus (5,2) and Medium-Plus (5,4) vehicles use the same engine as the Delta IV Medium, but have larger fuel and oxidizer tanks.

Delta 4 Heavy:

The vehicle features three of the common booster core rockets strapped together, seen here. At launch the rocket also will include an upper stage and a nose cone.

The Delta IV Heavy is designed to lift up to 13,130 kg (28,950 lb) to GTO. It joins three CBCs together for liftoff and uses the 5-m diameter second stage and tanks with a similar 5-m (16.7-ft) diameter payload fairing.

Delta IV Payload Accommodations

Two key elements make up payload accommodations hardware for Delta launch vehicles--the payload attach fittings (PAFs) that form the mechanical interface between the launch vehicle and the payload, and the payload fairings, which protect the payloads during the early ascent phases of flight. Boeing has built more than 400 payload fairings since 1957 and has a 100% fairing performance success rate to date. The company also has designed many different types of PAFs including:Commercial standards: 937 mm, 1194 mm, 1664 mm and 1666 mm

EELV standards: 1575 mm and 4394 mm

Platform dispenser for Globalstar? and post dispenser for Iridium

Dual payload attach fittings (DPAF) aboard Delta II and capability to provide DPAF for Delta IV

Delta IV Fairings

As with Delta III, the Delta IV family of Medium, Medium-Plus and Heavy launch vehicles encapsulates the payloads away from the launch pad, which reduces the required on-pad time to between six and eight days.

The Delta IV fairing designs and manufacturing processes have been proven. The Delta IV Medium and Medium-Plus variants use either a 4-m (13.1-ft) diameter composite fairing, a stretched version of the Delta III fairing, or a 5-m (16.6-ft) diameter composite fairing, derived from the Delta III fairing.

The Delta IV Heavy vehicle uses a 5-m diameter composite fairing. The Delta IV Heavy vehicle also can use a 19.8-m (65-ft) long, 5-m (16.6-ft) diameter aluminum fairing that Boeing developed for the U.S. Air Force Titan program.

Delta IV Payload Attach Fittings

Delta IV provides a family of PAFs that are compatible with today's most common industry-standard interfaces for current and future spacecraft. A dual payload attach fitting capability (DPAFC) similar to Delta II has been developed for Delta IV, which is available upon request. For details about Delta IV fairings and PAFs consult the Delta IV Payload Planners Guide.

Information And Images From Boeing.com and news articles